By Stuart Leuthner

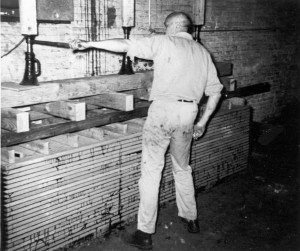

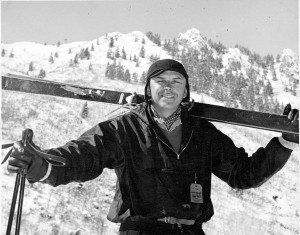

A skiing vacation during the winter of 1947 led Howard Head, an engineer at the Glenn L. Martin Company who skied badly, to revolutionize skiing.

Howard Head revolutionized two sports. He didn’t set out to do this; it grew out of his enthusiasm for skiing and tennis as recreation, which led him to use his natural inventive talent to try to make them better.

When a reporter asked Head how he invented, he said, “I invent when it’s something I really want. The need has to grow in your gut. People who go around trying to invent something generally fall on their tails. The best inventions come from people who are deeply involved in trying to solve a problem.”

During the winter of 1947, Head and some friends took the train to Stowe, Vt., for a ski vacation. Head, an engineer at the Glenn L. Martin Company, enjoyed the experience, but was “humiliated and disgusted” at how badly he skied.

On the ride back to Baltimore, Head and his friends discussed their adventures on the mountain. Rather than take all of the blame for his poor performance, Head put some of the responsibility on “those long, heavy, clumsy hickory skis.”

Head then told his traveling companions that there was no reason they should be skiing on wooden skis in these modern times. He would build a better ski from the materials used in the aircraft industry–aluminum and plastic.

“If wood were the best material, they’d still be making airplanes out of wood,” he said.

Skiing wasn’t an easy sport. Though the numbers were growing, there were probably fewer than 100,000 skiers in the United States immediately after World War II.

In the late 1940s, wooden skis weren’t dramatically different from those used by the Viking King Harold Hadrade in the 9th century. According to Icelandic legend, King Hadrade is considered to be the first recreational skier since he used his skis to “go fast.”

Heavy and unwieldy, they were long, flat runners carved out of solid wood, which curved up at the tip. They were about 10 feet long, three inches wide, and approximately one inch thick, and weighed between four and a half and five and a half pounds.

Hickory was the wood of choice, and although laminated skis were first developed in the 1890s, complex laminated skis didn’t appear until the late 1930s, when glues were developed that were strong enough to bond the laminations together permanently. In a laminated ski, thin layers of wood, called “canes,” were glued together, running the length of the ski. This method, called “split cane,” or “splitkein” in Norwegian (the technique originated in Norway), allowed the skis to be shaped while the pieces were glued together.

Laminated skis were superior to solid, hickory models. They were stronger, lighter and faster, and became a badge of honor for the skiers who purchased them. Manufacturers proudly advertised the number of laminations on their skis and the general consensus was the more laminations the better the skier.

Laminated skis, however, were far from perfect. Like their solid counterparts, they were extremely long and wide, terribly heavy by modern standards and required a great deal of muscle to make them turn.

Since a flat ski is extremely difficult to turn, an arch, or camber, is built into a ski. To maintain the camber, wooden skis had to be stored with a block in the middle, strapped at the toe and heel. No matter how well the skis were sealed, the wood would often get wet, resulting in warps and loss of camber.

Every few runs, wooden skis needed to be waxed to keep them from sticking to the snow. Their edges quickly grew ragged with turning on hard ice or snow. Despite their improvement over solid skis, even the best laminated skis broke.

Head wasn’t alone in thinking that metal could be used to make a better ski. The All Magnesium was first demonstrated at Sepp Ruschp’s Ski School at Stowe in 1942. Other early metal skis included the Alu-60, manufactured by the Chance-Vought Aircraft Company, the TEY True-Flex, the Dow Metal Air Ski and an English ski, the Goome.

Don Holly, better known for his carburetors, and Thor Groswold, who had been building wooden skis in Denver since 1932, teamed up to build the Holley Climactic Camber Ski. The theory behind the ski, constructed of wood, with an aluminum running surface, was that when the snow was colder, the metal would contract. This would cause the ski’s camber to increase, and hopefully, improve its performance.

Metal skis were more durable than wood and could go extremely fast. However, wax wouldn’t stick to the metal bottoms, and if the conditions weren’t perfect, they were impossible to move. They would also vibrate or chatter against hard snow, making them hard to control (because wood is a natural damper, wooden skis didn’t vibrate as much). And a collision could easily twist the metal skis into strange shapes. Skiers called metal skis “tin cans” and refused to buy them.

If Head was aware of these failures, it didn’t seem to faze him. Upon returning to his home in Baltimore, he began to sketch designs. The ski that he envisioned would be stronger, lighter and more flexible than those made out of wood. It would be based on the structural principles that he’d been working with at Martin: two layers of aluminum, bonded to sidewalls of thin plywood, with a layer of aluminum honeycomb in the center.

Working for Glenn L. Martin

It would take Head almost three years, and numerous attempts to accomplish what he set out to do, but in the end, his skis would change the sport forever. But as he toiled in his hot, grimy workshop in the summer of 1947, he might have been reflecting on how differently he had once imagined his future career.

The youngest of four children, Howard Head was born in Philadelphia, July 31, 1914. His father was a dentist, with a passion for classic literature, and his mother held a master’s degree in mathematics.

He wanted to become a writer, like his older sister, the novelist Hannah Lees, and when he entered Harvard, in 1932, he enrolled in literature and writing classes. Low grades soon had him on the verge of flunking out. He took an aptitude test and when the results revealed strong engineering skills, he switched his major, made the dean’s list, and graduated in 1936 with honors in engineering science.

Unwilling to give up his dream of becoming an author, Head went to work as a screenwriter for the March of Time newsreel company, but was soon fired because he spent more time fixing the film splicers than writing. After three more short-term writing jobs, including a stint as a copyboy for the Philadelphia Record, Head gave up.

“I always wanted to be a newspaper writer,” he said. “I had no talent, but I wouldn’t admit it to myself.”

In 1939, he was hired as a riveter at the Glenn L. Martin Aircraft Company in Baltimore. A year later, he was promoted to rivet gang boss, and when World War II began to heat up, Head was moved into Martin’s engineering department.

He was soon involved with the design of the B-26 Marauder, a twin-engine bomber. It was during these years at Martin that Head would become familiar with the materials and technology he would use to revolutionize two sports.

The B-26 was originally called the “Whore from Baltimore,” because its short wings suggested the airplane had “no visible means of support.” The airplane’s wings were ultimately lengthened, and the bomber went on to distinguish itself in both the European and Pacific theatres.

An innovative design, the B-26’s skin was a sandwich of an aluminum alloy called 75ST, which was stronger than cold-rolled steel of the same thickness, wrapped around a honeycomb structure. Skin sections were joined with butt-welded seams instead of overlapping ones, which increased the airplane’s top speed.

The Marauder was the first WWII vintage aircraft to use four-blade propellers and the first combat aircraft to use plastic on a grand scale. Martin had been pioneering the use of plastics to replace metal, and the B-26 contained over 400 such parts.

The Head Ski Company

While still employed at Martin after the war, Head conducted stress tests on 75ST and compared his data with those of hickory, which he found in engineering handbooks. When these tests convinced him that he could build a better ski out of metal, he rented the corner of an electrical appliance shop in an industrial section of Baltimore.

“I was a pretty good poker player,” he would write later. “I had about $6,000 put away; that was the money I used to start the Head Ski Company.”

Helping him in the shop were three mechanics (their number would ultimately grow to six) he had worked with at Martin. After they finished their shifts at the airplane factory, the men would moonlight at Head’s shop evenings and weekends.

Bonding the three layers was Head’s most difficult challenge, since the adhesive he was using–a thermo-setting glue used to manufacture shoes–required a combination of pressure and heat. To create 15 pounds per square inch of pressure, Head devised a rubber bag into which he put the ski “sandwich.” The bag was sealed, and the air was pumped out, through a tube attached to a refrigerator compressor. This created a vacuum, which squeezed the layers together.

The bag was then dropped into an iron coffin-shaped tank filled with oil heated to 350 degrees. Head described the work as “tough, dangerous and messy as blazes.”

“The smoke and smells were terrible,” he said. “Anybody passing by our shop at night must have thought we appeared to be more like alchemists of the middle ages than men of the 20th century trying to build a modern ski.”

Head left Martin and was now working full time in the shop. At the end of the first year, after producing six pairs of skis, he put them in his car and headed for Stowe.

“When I got there, I went into the lodge and found a group of ski instructors sitting in front of the fire,” he said. He told the men that he had designed a new metal ski and asked if they would be willing to try them out.

Ski instructors in those post-war days were for the most part Europeans, and extremely macho. One can only imagine what they thought of the tall, thin engineer, but his enthusiasm won them over and they agreed to meet him at the Mt. Mansfield Ski School the following day.

The next morning, when one of the instructors flexed Head’s ski to get a feel for it, it broke. The other men strapped on the remaining skis, and one by one, they too were soon in pieces.

“Every time one of them broke, some thing inside me snapped with it,” Head said.

The instructors left, laughing and shaking their heads, but one, Neil Robinson, stayed behind. He told Head that during the few minutes before the skis broke, he had “felt something.” If Head wanted to go ahead with his venture, Robinson said he would be willing to test future skis.

When Head returned to Baltimore, he took a hickory ski and conducted his own stress test on it. He was amazed to discover that hickory’s strength was two times what was stated in the engineering handbook. His design was too weak! He immediately replaced the fragile honeycomb with a marine-fir plywood core.

During the next two years, he and his crew built 40 different prototypes. Many years later he recalled, “If I had known then that it would take 40 versions before the ski was any good, I might have given it up. But, fortunately, you get trapped into thinking the next design will be it.”

Head would send several pairs of each version to Robinson, who would ski on them until they broke or delaminated. Robinson would then send them back to Baltimore, along with his remarks. Head would take the skis apart, looking for the flaws that caused them to fail, and make the necessary adjustments.

Take these skis and…

On a trip to Aspen, Head met Clif Taylor and Steve Knowlton, veterans of the famed 10th Mountain Division, who were teaching at the Aspen Ski School. Head had several pairs of his most recent skis with him and asked Taylor and Knowlton if they would try them out. The two instructors took the chairlift to the top of the mountain, and Taylor remembers their descent.

“At the top, in the powder, they were great,” he said. “I felt like I was floating. But, when we got about halfway down, where the snow was packed, I looked over and Steve was going sideways at what seemed like 60 mph.” He grimaces, “I was having just as much trouble because there was no way to control those skis in that snow.”

Then, as they reached the lower portion of the run, snow began to stick to the bottoms of the skis and the two men had to walk the rest of the way. When Taylor and Knowlton reached the bottom, Head rushed over and asked them how they liked the skis. Knowlton nodded at the ski’s polished surface and said, “You see that outhouse over there? You can take these skis and nail them to the wall (as mirrors) and guys can use them when they shave! That’s all these skis are good for!”

Knowlton stomped off, but Taylor, feeling sorry for the crestfallen Head, told him that the skis performed well in powder, but if he wanted them to be successful, his skis needed better edges (the soft aluminum would become dull after only a few turns) and a bottom that would hold wax. Like Robinson, Taylor told Head that he would be willing to try out future models.

Once again, Head went back to his shop. To solve the problem of ice and snow sticking to the bottoms, Head bonded a thin layer of phenolic plastic to the metal. Finding a way to give the ski better edges would prove more complicated. Many wood skis at the time had screwed-on metal edges. These not only prolonged the life of the ski, but also bit into the snow, allowing skiers to “carve” their turns.

Head’s engineering instinct recoiled from such a clumsy solution. He decided on a one-piece construction, which had the added benefit of strengthening the entire ski. Since the metal sandwich was fairly thin, the edge wouldn’t have to stretch too far, yet it would function as what Head called a “working sinew” of the ski itself. The final solution was a high-carbon, spring-steel edge, bonded and inlayed in the bottom layer of the ski.

By the spring of 1950, Head had arrived at his “final” design.

“I was out of money,” he said. “Either this ski was the right one, or I would simply have to close down the business and go out and get a job.”

Head hadn’t been paying his men for a year and a half–they were marking their time on a calendar. Head’s crew was a loyal bunch, but the ski maker sensed a mutiny was brewing. He called Taylor, knowing he was coming to the East Coast, and asked if he would stop by the shop and give his men a pep talk.

“At that time, Howard was living in a $20 a month basement apartment and washing his dishes in the bathtub,” Taylor said. “I told his men how great the skis were and I guess they believed me.”

Since it was late in the season, the only place to test the skis was Tuckerman’s Ravine, located on the southeastern side of New Hampshire’s Mt. Washington. Often called “the most dangerous small mountain in the world,” Mt. Washington is known for its violent weather and remarkable snow depths.

After you park your car, it’s a three-hour hike to Tuckerman’s, and once you arrive, there are no lifts. You want to ski, you climb.

The massive half-bowl’s sides are sprinkled with rock outcroppings, and most skiers are content to cruise the lower snowfields. Those who lust for an adrenaline rush climb the head wall. Once up there, the first challenge is to get your skis on, not easy on a pitch of 30 degrees or more. Falls that begin on the head wall often don’t end until the ravine floor, and sometimes are fatal.

Taylor was spending a week at Tuckerman’s, taking photographs for a book.

“Howard showed up with a couple pair of skis on his shoulder, and asked me if I would try them out,” he said. “He told me that he had to go back to Baltimore, but would return on the next weekend.”

For the next five days, Head’s “test pilot” skied on as many types of snow as he could find–early morning ice, afternoon crud, whatever–and when Head showed up on Saturday, he told him, “They’re working.”

Although he was gratified to hear that his skis were performing, Head wanted one more test. How fast would they go? He knew that consumers like to buy products that are used by champions. If he planned to sell a lot of skis, they would have to be used by the world’s best skiers.

“Howard asked me to take them to the top and let them run,” Taylor said. “So, I hiked up to the top of the head wall.”

As Head watched the instructor slowly climbing towards the rim, he would say later, “I was thinking to myself, my entire future is up on that mountain.”

Taylor continues, “Once you get to the top, it flattens out along the ridge. I wanted to do some turns, get a rhythm going, and then drop over the head wall.” He laughed, “Well, I came over the head wall, going like a bat out of hell, and missed my first turn. Howard didn’t know I was completely out of control.”

Taylor managed to get it back together, and after a few jump turns, he was soon carving his way towards the ravine’s floor.

“When I saw Clif coming at me, that fast and that surely, I knew deep inside that I had it,” Head said.

After a few more graceful arcs, Taylor stopped in front of Head in a shower of snow, and exclaimed, “They’re great Mr. Head. You’ve done it!”

Clif Taylor would go on to revolutionize ski instruction through his development of GLM, the graduated length method that started beginners on shorter skis, increasing the length as their skills developed. He also wrote three instructional books and produced over 20 films and videos on skiing.

As Head had discovered, lightness is not what makes a ski better.

“In trying to build a lighter ski, I accidentally created a ski that was stiffer in torsion–one that would turn and track more easily,” he said. “That was the magic difference. ”

Head’s metal ski resisted twisting approximately three times as well as a wood one. When a skier bends into a turn, the tips and tails of a wood ski bend away from the curve of the turn and the skier loses edge control. A Head ski could be maneuvered through a turn because it maintained a straight edge, enabling the skier to keep contact with the snow as the tip steers through the turn like the prow of a ship. The result was a ski that was faster in all kinds of snow, much more durable than any wooden ski, and softer in flex, so skiers of modest skill found it easier to handle.

Now that he had a ski that worked, Head applied for a patent–it was granted in 1954–and began to sell them. In 1950, he shipped 300 pairs to shops on trial consignment, and barnstormed across the country, hawking his new skis out of the back of his station wagon in ski area parking lots. The tall, balding ski maker was soon a familiar sight from New England to the Rockies.

Instructors soon found that they could make extra money selling Head skis. Wendy Cram, an instructor at Sun Valley, Idaho, sold 30 pairs out of his bedroom, and Neil Robinson sold them at Big Bromley, Vt., where he was director of the ski school. Even Steve Knowlton gave in, and instead of using them for men’s room mirrors, started selling Head skis at the Aspen ski school.

Head named his ski the Standard, and when he found the polished aluminum skin gave off distracting reflections and was prone to scratching, he added what would become his signature black plastic tops and side walls. During the 1950-51 ski season, he and two employees managed to produce 300 pairs of skis, grossed $12,000 and lost money. In 1951-52, Head made 1,100 pairs and broke even. A year later, he made his first profit, $1,200. In the early days, Head kept production costs at a minimum by doing most of the work himself.

He moved his operation, first to a two-car garage, not far from his original shop, and then to a building in the Hamden section of Baltimore. In 1959, Head built a factory in Timonium, Md. By the mid-1960s, the plant had 93,040 square feet of manufacturing and warehouse facilities and 12,628 square feet in office space.

Although Standards were expensive–$85, when the best wooden ski could be bought for $45–the skis caught on quickly. Anybody who was anybody wanted to be seen on a pair of shiny, elegant, black Head Standards.

They needed no special care, wouldn’t warp (or your money back), broke only under extreme provocation and were three times more flexible at the ends than wooden skis. More importantly, they turned easily in all snow conditions. Head’s “cheaters,” as they were soon called, opened the sport of skiing up to an entirely new group of enthusiasts, especially women, who found the heavy, wooden skis almost impossible to turn.

Head began to develop skis for specific uses, such as slalom or deep powder, and skis for the beginner as well as the serious skier. He awarded dealerships selectively, and he impressed on his salesmen that Heads were a quality product.

“Head skis are bought, not sold,” he told them.

Competitive skiers were much slower to adopt the metal skis, so he began working on a competition model. In 1956, he developed the first damping system for skis, inserting a neoprene layer in the top aluminum sheet. According to Head, not only did this reduce chattering at high speeds, it allowed the ski to “snake” over the terrain. By 1961, the system had been incorporated into Head’s Vector Competition.

In 1963, Switzerland’s Joos Minsch startled the world of ski racing when he won the Pre-Olympic downhill at Innsbruck on a pair of Heads. A year later, Head skis carried racers to medals at the 1964 Innsbruck Olympics. Two years later, one-third of all skiers in the top 10 of every major international race were on Head Competition skis–garnering a total of 18 gold medals, 15 silver and 15 bronze.

Building on the Competition’s success, Head introduced the 360 in 1967. An all-purpose recreational version of Head’s racing ski, the 360 would go on to become one of the bestselling skis in history. That same year, the Head Ski Company, with more than 500 employees, was grossing $25 million a year on the sale of nearly 300,000 pairs of skis in 17 countries.

But Head could sometimes get in the way of his own progress. During the early 1960s, a small group of designers began to consider fiberglass as the ultimate material for skis. Like metal, it was strong, and wouldn’t warp, but it had an additional quality; fiberglass is extremely damp. This results in better shock absorption and increased ability to follow the terrain, and allows the designer to alter the ski’s flex pattern.

The first true fiberglass ski, the Toni Sailer (named for a prominent Austrian skier) was introduced in the early 1960s, and other manufacturers were soon producing their own fiberglass skis. It was obvious that fiberglass would be the material of the future.

Ian Ferguson, a top salesman and manager at the Head Ski Company during the 1960s, remembers how stubborn Head was regarding the new material.

“Fiberglass skis were beginning to catch on with ski racers and instructors,” Ferguson said. “We told Howard that he should explore fiberglass, but he kept fighting us. He’d say, ‘Fiberglass is a flash in the pan. It will be gone tomorrow.’ The problem was pride of authorship. Howard had invented the aluminum ski and his ego was very much invested in it.”

By the end of 1969, the Head Ski Company had diversified into ski clothing and other athletic equipment. A new management team had been brought in and although he was still chairman of the board, Head was no longer in charge of the day-to-day operations.

“There comes a time when somebody like me has two choices,” he said. “He can sell or get swallowed up by the bigness of his own creation.” Head sold the company to the AMF conglomerate for $16 million.

During an interview, Head admitted that his passion for his metal skis caused him to miss out on the fiberglass revolution.

“I had lived and suffered with the metal skis so long, I just couldn’t let go,” he said. He continued, laughing, “I remember actually making the statement that glass only belongs in window frames.”

Even if he misread the importance of fiberglass technology, Head could retire, at the age of 55, knowing that he had reinvigorated the sport of skiing as well as touching off a major industry to serve all those new skiers. Since 1947, when he first hit the slopes at Stowe, the number of skiers in the United States had multiplied 400-fold to four million. From the time Head offered his Standards until the time he sold his company, ski manufacturing enjoyed 15 percent growth every year.

Edward Scott, the inventor of the aluminum ski pole, said of Head, “Howard brought stability and responsibility to a raffish, casual, irresponsible industry, peopled by hucksters and opportunists. By making a durable product that lasted for years and was disarmingly easy to ski on, Howard literally put America on skis.”

Tennis, anyone?

Howard Head, a “pretty good poker player,” started the Head Ski Company with about $6,000 he had put away.

Head moved to a comfortable estate in Baltimore and settled down to enjoy the life of a country squire. A year later, he built a tennis court on his property and discovered that his tennis was as bad as his skiing.

After endless lessons, Head’s frustrated instructor suggested that he should buy a ball machine.

“I hate to keep taking your money,” he told Head. “If you practice with the machine, there is the slim possibility that you might improve.”

Head described the machine he bought, made by the Prince Manufacturing Company of Princeton, N.J., as “ingenious, but so full of bugs it was almost useless.”

Instead of working on his backhand, Head took the machine apart and came up with a list of improvements he believed would improve the machine’s performance, which he shared with the company. He ended up buying Prince and within a few years after incorporating his improvements, the Prince ball machine controlled more than half of the market.

Although Head now had a ball machine that worked, he was still a weekend hacker. Again, he blamed his equipment, complaining that the racket twisted in his hand, sending the ball off in unexpected directions.

Tinkering in his workshop led him to decide that the racket needed to be bigger. A law of physics dictates that the wider an object is, the more resistant it is to twisting. This law also dictates that the polar moment of inertia increases as the square of the width. If Head widened the racket just one inch to either side, making it 20 percent wider, he would increase its resistance to twist up to 40 percent.

He checked with the U.S. Lawn Tennis Association regarding the rules governing the size or shape of a tennis racquet, and was elated to find they stated only that the racket is “the implement used to strike the ball.” Tennis rackets had remained almost unchanged since they first appeared in the eighteenth century. Wood limited a racket face to about eight and one half inches wide and ten inches long because bigger rackets were too heavy and prone to breaking.

Head began to fashion an oversize racket from high-alloy aluminum. For aesthetic reasons, he also increased the length of the racket by three inches. After a series of prototypes, he produced the first Prince in 1974.

Drawing on his earlier experience with skiing, Head put a Prince in 14-year-old Pam Shriver’s hand, and she took the racquet out on the junior circuit. Critics were soon comparing the new racquet to a snowshoe or spaghetti strainer, but they stopped laughing when, in 1978, Shriver became the youngest player ever to reach the finals of the U.S. Open. Five years later, every pro was using an oversized or mid-sized racquet.

Head also won a major coup when he was granted a patent for the Prince.

“When I first applied, the inspectors–who act as both judge and jury–refused the application, claiming that my idea was no more than an obvious extension of the state of the art in tennis racket design,” he said.

The Patent Office turned him down twice more, but that didn’t stop him. He once said, “The idea for an invention is only five percent of the job. Making it practical is the other 95. You have to have a perfectionist streak, and you have to let that streak run until the product works.”

Head now applied his perfectionism to the task of finding out what made his racket so special and proving it to the patent examiners. He set up a Prince ball machine in a lab to shoot tennis balls at a standard racket clamped to a vice. High-speed cameras recorded the racket’s coefficient of restitution, the ratio between the speed at which the ball hit the racket and the speed at which it bounced off. He knew that the highest coefficient for a standard racket was .57; in other words, the ball bounced back at 57 percent of the speed with which it hit the racket. But his experiments showed that the area where he could get this maximum return, called the “center of percussion, or “sweet spot,” wasn’t at the center of the racket, as he had supposed, but down near the handle.

He next found that the center of the Prince racket produced a coefficient in the low .50s–not bad, but less than the standard racket’s .57. As he aimed the shots farther down, however, the coefficients began to go up: .55, .58, .62, .67! He discovered that the sweet spot on the Prince was near the handle, as on a standard racket, but the coefficient was much higher, and the spot was almost four times larger than the standard racket’s.

“We were startled to discover that the best place to hit the ball was in that three-inch area of added length, an area that doesn’t even exist on conventional rackets,” he recalled. “It’s about two-thirds of the way up from where you grip the racket–the throat of the standard racket!”

Besides clarifying the physics behind racket design, Head’s discovery helped him persuade the examiners to grant him a patent. They conceded it was a totally unexpected outcome resulting in an invention. By luck, in his efforts to reduce twisting, he had stumbled onto an important discovery that changed how the game is played.

The Prince appeared just as the sport of tennis was beginning to boom. By 1976, the company had 50,000 orders for the racquet, and four years later, Prince was the fastest growing tennis racquet in the world.

Just like the Head ski, the Prince took hold among recreational players before they began appearing on the professional tour in large numbers. For weekend players, the Prince simply carried them to the next level, but for professionals, the Prince changed the game itself. As longer, fluid strokes were replaced by shorter, choppier ones, power became the essence of professional tennis.

In 1982, Head sold his interest in Prince to Cheeseborough Ponds for $62 million. He retired again, this time permanently, splitting his time between Baltimore and a condominium in Vail. He never did achieve the high level of play he aspired to when he reinvented the tennis racket; Pam Shriver believed he was quite frustrated about that fact.

Although his inventions wrought massive changes in two sports, and earned him a fortune, Head’s personal life was less successful. He was married four times, and had one daughter. His single-minded attention to his work was legendary and associates would sometimes describe him as “the boring engineer who knows everything.” But he was determined to change that.

In an interview after his second retirement, Head stated, “I’m giving up the thing world and heading into the people world. In part, my devotion to the creative side was due to my isolation from people. If anyone ever thought of me, they’d use the adjectives prickly and arrogant. The drug of creativeness is so powerful that a person can go on and on until he dies old and lonely. I have no interest in doing that.”

He got a little help in the people world when he met Vail resident Martha Fritzlen, who liked to ski as much as he did. They were married in 1984.

Howard Head became well known for his philanthropy. In 1991, Baltimore’s Center Stage Theatre dedicated the Head Theatre, named for the inventor and his wife, as a tribute to their years of support. He also contributed to the Baltimore Museum of Industry–which has a permanent Head/Prince exhibit as part of their Maryland Milestones Gallery–the Enoch Pratt Free Library, the Baltimore Symphony, the Walters Art Museum, the Johns Hopkins University, the National Aquarium, and many other institutions.

Howard and Martha Head provided the funding for the Howard Head Sports Medicine Center at Vail. Today, the center is one of the world’s leading clinics for treating sports related injuries in the world.

During the late 1980s, Howard Head’s health began to fail. He died of complications after heart surgery on March 4, 1991.

Reflecting on his business success, he once told an interviewer, “There is a part of the male human being that has to be satisfied by the creative and productive part of his life drive. But this is not the whole part. There are also parts that have to do with living and people and having fun, and liking yourself and all that stuff, and those are quite unrelated to the business success. I am quite satisfied with the business success, but there is a lot more to living than that.”