Museum to prepare “Adam Push Pull”

|

“The Skymaster was a great concept, however it didn’t work well due to the metal and rivets,” said Knudsen.

The CarbonAero is the vision of George F. “Rick” Adam Jr., CEO, who, “frustrated with the lack of progress in general aviation, set out to develop a modern, technologically-advanced aircraft incorporating safety, performance and economy unavailable in the market today.”

Adam and Knudsen formed Adam Aircraft Industries in July 1998. Adam commissioned industry icon Burt Rutan, founder of Mojave-based Scales Composites, Inc., the developer of over 30 original aircraft types, to take the new aircraft design from concept to prototype in just seven months. Rutan dubbed the proof-of-concept aircraft the M-309 because it was the 309th design to come off his drawing board; the designation stuck.

Knudsen and Adam are working in tandem on the continuing development and manufacturing of the state-of-the-art aircraft. Adam Aircraft’s use of lightweight carbon composite to construct the CarbonAero gives the aircraft several advantages.

“First, the structural workability is important,” Knudsen says. “Using fibers in the composite fabric, we are able to be oriented in directions that are best suited for the design. Designers can manipulate fibers in the direction that will provide the greatest amount of efficient structure.”

Unlike metal, says Knudsen, composites are not subject to corrosion from natural or manmade elements, and have a high resistance to fatigue damage. In addition, composites lose little structural integrity from ongoing use and can have unlimited airframe life.

“Composites have a lower density than most metals, but for structural stability and other design reasons, composite airplanes usually weigh the same as metal planes,” explains Knudsen. “By using a greater amount of lighter material, structural parts like skins are relatively thicker. The result is a stiff, solid aircraft, which can safely withstand exterior loads, cuts and abrasions.”

Knudsen says it’s common for the light skins of a small airplane composed of metal to buckle, “like a soda can,” while under normal flight conditions.

“This isn’t the case for a composite airplane,” says Knudsen. “A composite aircraft benefits from this stiffness, yet provides better dampening (less vibration transmission) features, creating a soundproof structure.”

Composite manufacturing allows the incorporation of complex curved surfaces with fewer seams and rivets.

“The absence of these rivets and seam lines provide a smooth, uninterrupted airflow area, which translates into increased fuel efficiency,” Knudsen says.

Another advantage of using composites is its simple assembly; many of the fasteners and small parts can be replaced with larger, more integrated structures.

Teledyne Continental TSIO-550 engines, 350-hp, also utilized by Lancair Columbia, Beechcraft, Mooney, and other manufacturers, power the aircraft. The CarbonAero utilizes FADEC (Full Authority Digital Engine Control), a computerized fuel control system that reduces pilot workload with single lever control of each engine, while improving fuel economy and engine performance.

The CarbonAero, with three bladed Hartzell props, and retractable tricycle, trailing link landing gear, will have a ceiling certified to 25,000 feet and will climb at a maximum rate of 1,700 fpm. At 20,000 feet, the airplane will have a maximum speed of 250 knots and will cruise at 220 knots, with an economy cruise of 200 knots. The cruising range will be 1,500 nautical miles, when operating in fuel economy mode.

The CarbonAero will have a maximum useful load of 2,300 pounds and a maximum fuel capacity (useable) of 250 gallons. It has a wingspan of 44′, and is 36.7′ long and 9.5′ high. The cabin length is 13.6′ long by 4.5′ wide. Cabin height is 4.3′.

Adam Aircraft has already exceeded $22 million in sales.

“We’ve been flying our airplane to all of the major aviation shows and have taken deposits on 33 delivery positions thus far,” says Knudsen.

CarbonAero owners, says Knudsen, are typically pilots that currently own a Cessna 210, Beech Baron, or Bonanza, fly for business or pleasure, and are looking for an “affordable, pressurized, twin-engine aircraft with more space.”

Out of the 33 airplanes sold, the first 20 went for $695,000; the other 13 have sold for $725,000. Currently, the price of the CarbonAero is $750,000. And, Knudsen says, they intend to keep the aircraft affordable by keeping the price under $800,000.”

“There’s a tremendous demand for new airplanes in this range,” he says.

Even with an affordable price, Adam Aircraft anticipates that many pilot/executives will pool resources to acquire a CarbonAero, dividing the cost of conducting business.

Tom Wiesner, vice president of sales and marketing, says that those purchasing the aircraft include those who want a “safe, twin-engine” that employs “simplicity in operation, modern technology in design, and state-of-the-art equipment.”

CarbonAero’s standard equipment includes a basic IFR package—dual NAVCOM, GPS, and dual EFIS—autopilot, leather interior, club seating, carpeting, and cabin heat.

The option list, says Knudsen, is what could drive up the price. CarbonAero optional equipment include air conditioning, de-ice, galley (several options), avionics upgrades, auto pilot, and entertainment system. One item not offered at this time is a toilet; Knudsen says they haven’t had one request.

Knudsen says that as Adam Aircraft moves forward towards certification, their commitment to produce aircraft for “safe and affordable air travel worldwide” is stronger than ever.

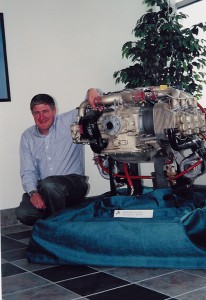

John Knudsen, president for Adams Aircraft Industries, next to the Continental TSIO-550 engine, which powers the CarbonAero.

Finding Arapahoe County and the metro Denver area an attractive market for hiring “expert staff,” this year, Adam Aircraft established headquarters and their manufacturing facility at Centennial Airport, where they plan to eventually build 100 aircraft per year.

Phase I includes 55,000 square feet of office, research and development, and manufacturing space for the CarbonAero and subsequent versions (possibly in the turbine category).

COO Cecil Miller, together with a large group of talented engineers, is moving the CarbonAero through the type certification process.

Adam Aircraft is setting a precedent in this area. Working with the Denver Aircraft Certification Office, they have been approved to submit required drawings and engineering documents to the FAA, expected to certify the CarbonAero in 2003, via the Internet.

Key Personalities

Employee-owned Adam Aircraft believes their employees “make all the difference.”

“You have to give people credit for their talent, hard work and loyalty,” says Knudsen. “It’s only fair they have a vested interest to see our company succeed.”

“We have the cream of the crop here,” says Knudsen.

Adam, the sole investor in the company, has earned a name in both the aviation and business community. He attended the U.S. Military Academy, West Point, where he received a Bachelor of Science degree. He served as a captain in the U.S. Air Force and was a launch crew officer in charge of the Real Time Computer Center at Kennedy Space Center for Apollo missions 8 through 14.

While in the Air Force, Adam attended graduate school at both Florida State University and Golden Gate University, where he received his MBA.

Presently, Adam, who started flying while in his early 40s, has logged about 1,500 flight hours and holds a commercial pilot and multi-engine rating certificate, as well as type ratings for the Cessna Citation Jet 525 and 650.

Prior to founding Adam Aircraft, Adam was a general partner with Goldman Sachs and Co., where he directed a staff of 2,500, and was responsible for initiating and completing a successful turnaround of Goldman’s IT operations.

Adam also founded the Goldman Sachs Trust Co., Global Custody Business and Securities Lending Business. He held executive positions at Baxter Healthcare Corporation, FMC Litton Industries and IBM.

He formed Arapahoe County-based New Era of Networks (NEON), an integration software company, which he sold to data base company Sybase in July 2001. Presently, Adam is vice president of the company’s E Business Systems.

Prior to joining Adam, Knudsen, who serves as Adam Aircraft’s general counsel, worked in a Denver law firm, Byrne Kiely & White, specializing in aviation law. Knudsen, who received a BS in business from the University of Colorado in 1974 and a Juris Doctorate from the University of Puget Sound School of Law in 1987, spent five years as trial counsel with the FAA in Washington, D.C. His legal expertise range includes issues such as crash litigation, product liability, insurance defense, aircraft transactions, FAA regulatory enforcement, certification and general corporate and civil litigation.

His aviation career includes time spent flying numerous aircraft, including the A-6 Intruder and A-4 Skyhawk as a U.S. Navy pilot. During his stint in the Navy, Knudsen logged over 150 aircraft carrier landings. His last assignment was as a patrol plane commander in the P-3 “Orion” with the Navy Reserves.

Knudsen served as project manager for cloud-seeding operations in Spain and Libya, which included a solo transatlantic flight he made in a Piper Navajo. He also flew as captain for a commuter airline. He currently holds an airline transport pilot certificate and is type certificated in the Learjet and Citation 525SP. He has logged well over 4,000 flight hours.

Wiesner is a graduate of Embry-Riddle Aeronautical University; he has a BS in Aeronautical Science. He served 14 years in the U.S. Army, attaining the rank of major. He commanded two different aircraft companies overseeing a staff of 85, 18 aircraft, and associated assets in excess of $100 million. Currently, he is a major in the U.S. Army National Guard.

Wiesner has logged more than 3,500 hours of flight time in airplanes, helicopters and jets. He holds an airline transport pilot certificate for multi-engine aircraft, has a type rating in Citation Jets, holds a commercial certificate for single-engine airplanes and helicopters, and is a flight instructor for airplanes and helicopters—all with instrument privileges.

Prior to his position with the company, Wiesner served as president of Rocky Mountain ExecJets, a Centennial Airport-based fractional ownership company.

Miller has 35 years of experience in aircraft manufacturing, and has been responsible for developing manufacturing systems from design creation through final processing.

Prior to joining Adam Aircraft, he was the vice president of operations at Cirrus Design Corp. in Duluth, Minn., where he developed, certified and established the complete operations plan for the company. He also served as vice president of operations for Raytheon Air Corp., and vice president of manufacturing for Beechcraft, where he dealt with all facets of manufacturing.

As Adam Aircraft grows, they expect to have service centers for their aircraft around the country, with an in-house flight department, and maintenance and parts divisions.

“Right now we have 65 employees, but we plan to hire 30 more in the near future,” says Knudsen. Adam Aircraft plans to exercise an option on another parcel of land at the airport, where they will add an additional facility that will house manufacturing operations.

“Within five years, we anticipate having 500 employees, which will make us one of the largest general aviation manufacturers,” says Knudsen.

Adam Aircraft continues to offer delivery positions on a first come, first serve basis, and is on schedule to make their first delivery immediately upon certification. Delivery positions can be secured with a $25,000 fully refundable deposit.

For more information, call 866-232-6247, or visit www.adamaircraft.com.