By Eden Hopkins

Restoration and conservation are a big part of a museum’s responsibility, both to history and to its visitors. At The Museum of Flight these efforts are undertaken by a largely volunteer force whose dedication and expertise is exceeded only by their love of everything aviation.

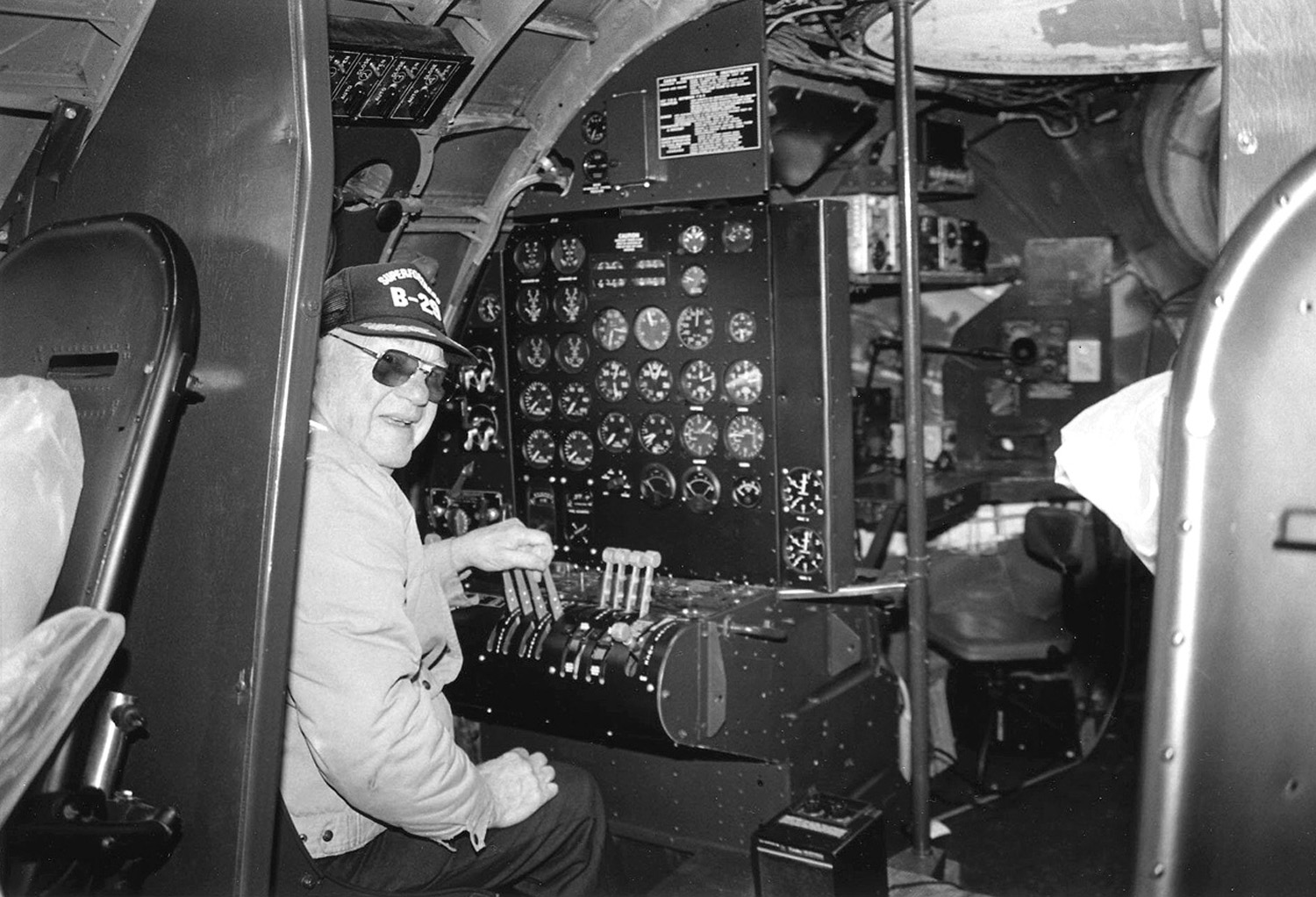

Crew chief Dale Nicholson takes the controls in the flight engineer’s station. Nicholson has been on the B-29 project since “T-Square-54” arrived from Lowry AFB. He trained as a flight engineer on the B-29 during World War II.

Less than a mile from the museum, in a rented space in Boeing’s historic Plant 2, are two of the museum’s crown jewels—a B-17F Flying Fortress and a B-29 Superfortress. The B-17—the only airworthy “F” model in the world — has already been restored to a stunning standard of authenticity and now awaits only an appropriate display space. But the B-29 is still the focus of an intensive restoration effort by museum volunteers.

“T-Square-54,” as the Museum’s B-29 is known, was built in Wichita, Kan., and delivered to the U.S. Army Air Corps in January 1945. It served as a replacement aircraft, flying 37 combat missions over Japan before the end of World War II. Since it was a spare aircraft not assigned to a specific crew, the plane lacked a colorful name and nose art. Instead it was simply known by its tail markings: “T” represented the 498th Bomb Group, the square symbol was for the 73rd Bomb Wing, and the number 54 denoted the fifty-fourth B-29 assigned to the group.

Since arriving at The Museum of Flight in 1993, “T-Square-54” has gotten refurbished wing panels, control surfaces, bomb bay doors, control cables, cockpit instruments, wiring and central fire control systems. The amount of work completed has been immense—and the amount remaining is also immense. This article tells the story of one small but important part of this huge, multi-year project—the rebuilding of the tail-gunner’s compartment and turret mechanism—and in so doing, reveals the daunting scale of this sort of restoration project.

After its wartime service, the tail turret and armor plate were removed, and “T-Square-54” was fitted out as a tanker with an aerial refueling boom. On retirement, the aircraft was sent to Naval Air Weapons Station China Lake in California, where it was positioned on a test range for target practice. During this maneuver, bulldozers crushed the rear fuselage of the once-proud Boeing.

Fortunately, the Superfortress was saved before the Navy could blow it up. In an early cosmetic repair at Lowry AFB in Denver, the damaged lower tail compartment was hastily dummied up with sheet metal and fake gun barrels. But in 2001, the museum’s restoration team turned intensive attention to a complete—and authentic—restoration of the tail compartment and turret.

The compartment features an upper “cupola” with windows and an escape door, and a hemispherical lower section enclosing the turret mechanism and gun breaches. Museum restorers were able to salvage a semi-serviceable lower section from China Lake to replace the fake Lowry pieces. But when the team tried to match the China Lake lower compartment with the original upper compartment, they were confounded by mismatched rivet patterns. Project manager Tom Dawson suspects that the part from China Lake was built to a drawing revision not found in the museum’s B-29 documentation. Undeterred, the crew filled in the original rivet holes and added a backing plate to join the upper and lower portions.

During the past four years, tail compartment lead Syd Baker has contributed 80 percent of the work on the compartment. He machined the entire turret mechanism from the original drawings and traveled widely to photo-document other B-29s to assist the restoration—all gratis in support of a project he’s passionate about.

Volunteer James Forman welded a new three-foot-diameter aluminum ring and hardware to mount the guns. Then Brian Nordby created the outer domed shroud that covers the ring mount and guns. The hemispherical shroud allows the turret to move laterally. It was originally a stamped part, but lacking the original die, Nordby recreated it by hand using an English wheel and other special metal-forming tools.

Michael Singley of Pacific Aero Tec in Kent, Wash., is fabricating the five tail compartment windows. Syd Baker plans to cast special rubber window gaskets with new polymer, as the original material is no longer available.

And what would a gun turret be without guns? Baker cleaned the original rusted and pitted gun barrels and has accurately replicated the rest of the gun mechanisms and mounts. Dave Miner of Machinists Inc. in Seattle contributed aluminum stock for this part of the project. Determined to make the turret fully operable, the restorers purchased or traded for the missing drive motors and gear boxes. Volunteer Dale Thompson is working on the wiring and controls to enable the turret to be remotely controlled-—just as it originally was-—as well as to generate simulated gunfire sounds. The crew plans to build an external sighting station that will one day enable visitors to learn firsthand how the gunner sighted the guns and controlled the turret remotely.

The crew will also recreate the original canvas boot that sealed the gaps between the gun barrels and the turret shroud. Volunteer Jack Korsten, who “cut his teeth” creating the canvas wheel covers for the immaculate Boeing S-307 Stratoliner restored by The Boeing Company for the Smithsonian National Air and Space Museum, is now working on the B-29 boot.

Most of the crew’s work on the tail compartment will never be seen once the tail is closed up, but the restorers want to do it right; knowing that their work is accurate is reward enough for these dedicated perfectionists. The team hopes to reinstall the completed tail compartment on the bomber within the next year.

The museum’s B-29 restoration effort is always in need of resources. If you’re interested in learning more about how you can support the restoration of “T-Square-54,” please call 206-768-7174 or e-mail jbrooks@museumofflight.org to sign up for the museum’s free quarterly publication, B-29 News.