Basler Flight Service becomes a very busy place during EAA AirVenture Oshkosh. While hundreds of people pass through everyday, the staff is always friendly and accommodating.

By Henry M. Holden

In 1957, Warren Basler opened his fixed base operation, Basler Flight Service, at Wittman Regional Airport (OSH), about 90 miles north of Milwaukee, in Oshkosh, Wis. At the time, he couldn’t have predicted that in 1970, when the Experimental Aircraft Association moved to Oshkosh, his small FBO would become part of the largest annual aviation event in the United States. He also couldn’t have foreseen that his passion for the Douglas DC-3 would lead him to create a new aircraft type, the BT-67.

Warren Basler was born on a farm six miles south of Wittman. In 1943, on his 17th birthday, he soloed in a Piper J-3 Cub. He logged more than 26,000 hours as a pilot, with more than 10,000 hours in the DC-3 type. Until his tragic death, along with three other Basler employees, in a March 1997 midair collision, Basler and his wife Patricia together ran the family business. She remained active in the business after his death until 2002.

Basler Flight Service

This picture of the ramp at Basler Flight Service only hints at the volume of aircraft they handle. To the left and out of camera range are several dozen more airplanes.

Surrounded by dairy farms, Basler Flight Service fuels an average of 200 aircraft per month. Oshkosh has about 80,000 residents, but for the EAA’s AirVenture week, the last week in July, the population balloons to about 650,000 people. During that week, the FBO’s business changes dramatically; they fuel 4,000 aircraft. In order to handle the load, Basler Flight Service operates two remote fueling locations on the EAA grounds, so pilot-visitors can fuel up before departing for home.

“We spend months in advance, preparing for what seems like a tidal wave,” said Mary Garcia, the FBO manager. “A few days before EAA opens, we begin to see arrivals for the fly-in. Then the floodgates open. Every day is a little different. The FBO has an advanced reservations system, but last-minute reservations or arrivals always show up. A pilot passing through may stop for fuel. We put this quick turnaround in the slot and go from there.”

L to R: Basler Flight Service employees Mary Garcia, Andrea Albright, Laurie Donker, Kathy Schoenrock, Holly Kananen and Mary Johnson take a moment to smile for the camera during their busiest week of the year.

She also said they get many unexpected customers who aren’t aware of the air show until the last minute, but then decide to come.

“Our customers have small aircraft, such as a Bonanza, but some are as large as a trijet,” she said. “They come in from all over the world. Some organizations come in that aren’t tied into the air show week.”

Garcia says the preparations begin early.

“As a courtesy to our customers, we send out ramp reservation forms on March 1,” she explained. “But we start taking reservations in January, if someone wants to plan their vacation early.”

AirVenture week accounts for about one-third of Basler’s yearly business.

“Normally we have two fulltime employees and eight part-time people in the FBO,” said Garcia. “For this one week, we bring in 53 additional employees to cover our office staff, courtesy vans and fuel booth staff, and then we divide them among all the shifts. Of the additional employees we bring on, about 80 percent of them are return employees.”

Fuel controversy

Warren and Pat Basler enjoy a boat ride on Lake Winnebago in Oshkosh, Wis. Warren Basler was one of the pioneers of turbine technology in the U.S.

For the past three years, while dealing with the daily operation of an FBO, Basler Flight Service has been embroiled in a serious legal battle. An Oshkosh competitor, Orion Flight Services, sued Basler, after Orion’s attempt to under-price Basler on fuel prices. This past May, the Wisconsin Supreme Court ruled for Basler, saying that Wisconsin’s minimum markup law doesn’t apply to aviation fuel. The court ruled that the minimum mark-up provisions, which require that motor vehicle fuel prices must include a profit of up to 9.18 percent, don’t apply to aviation fuel sold in Wisconsin.

“We’re obviously pleased with this ruling,” said Rod McNeil, Basler Flight Service president. “It’s been a long and expensive process to prove that aviation fuel is really a different product and in a different market than automotive fuel.”

The FBO hours are Monday through Friday, 7:00 a.m. to 7:00 p.m., and Saturday and Sunday, 8:00 a.m. to 5:00 p.m. With advance notice, 24-hour service is available. Basler Flight Service offers a flight planning area, private conference room, private pilot’s lounge, high-speed Internet access, free transportation to area restaurants and hotels, plus free use of two crew cars.

Basler Turbo Conversions LLC

Tom Weigt, president of Basler Turbo Conversions, LLC, says, “The philosophy inherent in our manufacturing process is to exceed industry standards by following an uncompromising approach to excellence that produces a product of the highest quality.”

Six years after he opened his FBO, Warren Basler bought his first DC 3. He refurbished it and sold it to a customer with whom he would become a partner in a charter flight service.

Before Warren Basler formed Basler Turbo Conversions in 1988, Basler Flight Service had reworked hundreds of DC-3s, modifying interiors, restoring airframes and overhauling engines. Today, Basler Flight Service is a division of Basler Turbo Conversions LLC.

In 1982, Basler spent $2.5 million to build a DC 3 turboprop conversion for Friendship Air, in Fairbanks, Ala. He replaced the standard 14 cylinder radial engines with two PT6A 45R turbojets, which boosted the speed from 165 to more than 200 miles per hour. By 1989, those engines had accumulated more than 5,000 hours of trouble free operation.

Basler recognized that aging DC-3s needed engine and airframe enhancements and became involved with several modification concepts. Later, with two aircraft and a wish list, he began the modification and certification process.

The FAA granted Basler Turbo Conversions a parts manufacturing approval for the parts it manufactures in-house. The FAA’s Manufacturing and Inspection District Office still retains manufacturing oversight.

Basler built a $3 million, 75,000-square-foot modification facility adjacent to Wittman Regional Airport for his conversion work. Seen here are ships number 49 and 50 undergoing conversion.

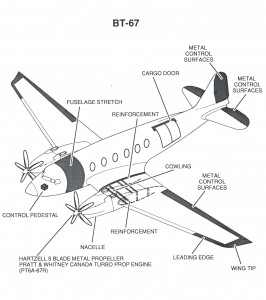

The major modifications to convert a DC-3 to turbine power are made under a supplemental type certificate SA4840NM, which was issued in Feb.1990. Full certification was granted in Dec. 1990. That year, Basler had 10 orders for the converted DC-3, called the Basler BT-67.

In the course of six months, the modification of a DC-3 takes place in three major areas: airframe, engines and props. The airframe is returned to its original specification. The radial engines are replaced with new Pratt & Whitney Canada PT6A-67R turboprop engines, certified to FAR Part 33, Amendment 10. Less maintenance is required for these engines, because overhaul time is at 6,000 hours versus 1,200 for the radial engines. Hartzell five-blade metal propellers replace the three-bladed props. Basler-converted airframes are “zero-time,” with respect to mandated inspections.

The company inserts a 40-inch plug in the fuselage, forward of the wing. This increases the airframe’s volume by 35 percent, and moves the cabin bulkhead forward five feet. Without this plug, the new props would be right outside the pilot’s window.

Basler’s first BT-67 turbo conversion was sold to Policia Nacional of Colombia. Seen here, it’s back for systems upgrades. The ship was used in the initial flight test program.

“We didn’t think it was a good idea to have the ice shields in line with the cockpit,” said Tom Weigt, president of Basler Turbo Conversions.

“A fully loaded BT-67 has a slower approach speed than a comparably loaded DC-3. At 10,000 feet, the PT6A 67R engines pull the BT-67 along at 230 mph, and burns 150 gallons per hour of jet fuel,” said Weigt.

The FAA required improved wing performance, and longitudinal stability and control for the new engines.

“On the old DC-3, the wing stalls as a whole, and you lose aileron control,” explained Weigt. “Adding a wing cuff (a leading edge droop) increased the wing area effect. The cuff causes the outer wing to stall last, and keeps airflow over the aileron, which improves stall behavior.”

The Basler DC-3 parts inventory is enormous. Tom Weigt is opening just one of the 18 “C” containers that store DC-3 parts.

An old expression stated that everything on the DC-3 had been changed except its shadow.

“Since we’ve lengthened the airframe, and modified the outer wing leading edge, wing tip and tail, the BT-67 even has a new shadow,” Weigt said.

Basler can convert an owner’s existing DC-3 airframe, or provide an airframe for conversion.

“We’re getting fewer requests to covert the owner’s airframe,” said Weigt. “The airframe condition is probably more important. Airframes with relatively little corrosion and a good maintenance history are what we are more interested in. We recently obtained the Miami Valley Aviation (Ohio) fleet of six DC-3s. All but one is in airworthy condition.”

The performance of the BT-67 is well known, and others are now looking at it for specialized applications.

The cockpit on a BT-67 is clean and orderly, and some glass instruments make piloting chores easier.

“We have customers telling us, ‘This is a good platform for survey work, for maritime patrol activities and even tactical maritime patrol,'” Weigt said. “We’re seeing expanded interest in those applications. I think that’s because we live in a very troubled world. The official U.S. product for those operations is the AC-130 Hercules, which is a high-dollar product. We’re the ‘low-price spread,’ but we can still get the job done.”

The airplane has proven itself to be such an excellent platform for surveillance and tactical interdiction activities, Basler is concentrating on new military applications, such as search radar and advanced communications and intelligence equipment.

“The BT-67 can loiter over an area for ten hours, monitoring and downloading information,” said Weigt. “It’s low cost, and it keeps human intervention in the mix. We’re a low-altitude application, at around 5,000 to 15,000 feet, where our infrareds are most effective. We do, however, have the capability to fly at 25,000 feet.”

Basler Turbo Conversions is currently working on its 50th conversion.

“What distinguishes us from other companies is we keep improving our product,” said Weigt. “Often a company goes through a strenuous development period, and then it becomes a fixed product. We’ve kept ours fluid. We keep making little improvements and small changes. We’re a lot more agile, and that’s what has kept us in the game.”

Basler Turbo Conversions is active in international markets, including Europe, the Far East, the Pacific Rim and Africa.

The bubble below the nose of this BT-67 gunship is the forward looking infrared camera. All BT-67s have over-wing exhausts to minimize their infrared signatures.

“In the last six months, we’ve delivered two BT-67 aircraft to Colombia, one to Colombian police, and a new gunship to their air force,” said Weigt. “In addition to our Central, South American and Antarctic customers, we also serve the U.S. Forest Service, U.S. Air Force, Thailand, the Republic of South Africa, Mali and Mauritania.

“Our number-one driver has been the customer asking, ‘Can you do this?'” he said. “A lot of companies talk about listening to their customers, but it’s a lot tougher to practice it than to talk about it. When you’re able to do it, it’s worthwhile.”

The basic BT-67 aircraft costs $4.5 million, and an aircraft equipped with maximum capability would run $13-plus million. Such an aircraft is classified, but it would probably contain search radar, infrared, intelligence of some level, listening devices, secure communications, night vision compatibility, an on-board oxygen generation system and probably a gun capability.

“Every year we make some changes,” said Weigt. “Most of them come from our customers who ask, for example, ‘Can you build a glass cockpit?’ ‘Can you take some weight out of the aircraft?’ ‘Can you improve the performance?’ ‘Can you give us a military flight manual?’ they’ll ask. The good thing is we can respond to them. When the request comes in, we take action.”

The side-facing seats fold up, as seen on the right. Removing the forward-facing seats allows seating for 40 troops.

One area where change has made a significant difference is in the gunship (nicknamed Fantasma). The gunship can climb to 15,000 feet, and isn’t pressurized.

“With the old oxygen bottle system, we had four bottles,” Weigt said. “If someone was shooting at you and hit one of the bottles, you became a flying bomb. To give the crew some protection, we had to add armor protection around the bottles. Then you had 600 pounds of weight added to the airplane, and the oxygen was still dangerous. The new OBOG is very low in pressure, around 40 psi, compared to the 1,800 psi in the bottles.”

Basler trimmed more weight by reengineering the floor.

“We used to use the old Fruehauf-style heavy duty truck floor, out of truck trailers,” said Weigt. “It was a good floor, but it was too heavy. We took that concept and retooled it. Now, we make our own floor. It is much lighter, reducing the weight by 350 pounds.”

He said next year they’ll introduce a cockpit that’s totally night vision compatible.

“All of the panel lights had to be modified, so they wouldn’t interfere with night vision goggles,” he said. “Every switch has its own light source. With just one switch, everything goes from day to night or from normal to night. Everything is filtered. Even at night, you’ll see color on the weather radar.

The military wanted better single-engine performance, so Basler Turbo Conversions introduced a new propeller that improves performance, particularly in a single-engine emergency. In military situations, it allows the aircraft to carry large loads in and out of high-altitude airports. With that change, Basler also introduced a military operations flight manual.

The BT-67 is certified to colder temperatures, below -50C, for Antarctic customers.

This line drawing of the BT-67 shows the external changes made to the old DC-3. Metal control surfaces replaced the old fabric surfaces, greatly reducing maintenance.

“That, combined with a new battery system exclusive to Basler, is important for our customers,” said Weigt. “It’s a non-hazmat battery that’s virtually maintenance free. We tried the recombination technology batteries, and found them to be 80 percent stronger, lighter and more durable. They cost less, and don’t require special procedures for hazardous shipping. More importantly, they suffer far less power depletion in extreme cold than we found with lead acid batteries. The polar applications are an important market for us. Things like that keep the business refreshed and our customers coming along.

He said a lot of the credit for the company’s success has to go to the founder.

“Warren got us to the starting point, and we’ve built on it,” Weigt said. “We haven’t altered it. The way to recognize his work is to make something out of it and keep improving it.”

Weigt said aviator and entrepreneur Jack Goodale, Basler’s new owner, recognizes the value of what they do.

“He’s built an incredible infrastructure,” Weigt said. “We have an unbelievable stockpile of DC-3 parts. The barn is full, so we have 18 ‘C’ containers out back, filled with more DC-3 parts. That’s the beauty of the DC-3; a lot of parts are still around.”

Warren Basler once described the DC-3 as a “beautiful, stable and virtually indestructible airframe going to waste.”

“We realized that by turbinizing and modernizing the airplane, it would go on for many years,” Weigt said.

He was right. The turbo conversion should take the old DC-3 to its 100th birthday and beyond.

Basler Airlines

The clamshell cargo door is similar to one used on the C-47 version of the DC-3. Basler added an upper lip on the door that allows five LD3 containers to be loaded. FedEx and UPS use the LD3 containers.

Basler Flight Service grew quickly and soon spun off the Basler Airlines division, flying passengers and cargo in DC-3s and other twin-engine airplanes. Basler became a well-known and highly respected name in this area. Basler Airlines helped make aviation an affordable tool for businesses, both large and small, which had the need to move people and cargo around the world.

Today, Basler Airlines operates as an on-demand cargo airline, under FAR Part 135. Basler Airlines flies the first Basler turbine DC-3 (DC-3TP), an earlier version of the BT-67, with the same airframe design but differences in systems, engines and performance. The DC-3TP turbo conversion can haul up to 7,500 pounds, with room for cargo six feet tall in 42 feet of cargo space. A flight crew is on call 24 hours a day, 7 days a week.

For more information, visit [http://www.baslerturbo.com].