By Eden Hopkins

It’s been more than a year since British Airways Concorde G-BOAG arrived at its new home in Seattle at The Museum of Flight. Part of the preservation plan for Concorde will be especially welcome to visitors. A newly installed HVAC system helps conserve this priceless artifact while also allowing visitors to tour Concorde in the comfort of a climate-controlled cabin during the winter months.

The museum’s previous HVAC experience with the first presidential jet “Air Force One” was one of many factors that contributed to British Airways’ decision to lend a Concorde for display in Seattle. British Airways representatives appreciated the museum’s ability to maintain aircraft outdoors, open to visitors even in Seattle’s sometimes inclement weather.

The main objectives of the HVAC system were to provide re-circulated air, energy efficiency, stable temperature and humidity levels, and visitor comfort. The importance of these systems in the humid Northwest climate cannot be over emphasized. Without an HVAC system, aircraft sitting outdoors will become filled with moisture and mold that can destroy historic aircraft, creating millions of dollars worth of damage. The Museum of Flight learned this lesson through its acquisition of the long decommissioned de Havilland Comet 4C jetliner that arrived at the museum’s restoration center at Paine Field in Everett, Wash., after 15 years on the tarmac.

In 1994, the museum acquired the Comet that had sat derelict at Paine Field since 1979. By the time the museum took possession of the jetliner, according to Bob Hood, Comet project manager, “The interior was saturated and wet, with surface moisture, slime and algae everywhere.”

“There was an inch of standing water in the cockpit,” he said. “Some of the support beams under the aft floor of the main cabin were so rotten you could put your hand through them.”

Corrosion from leaks took a heavy toll on the Comet, requiring lengthy restoration that is still not complete. Concorde’s HVAC system will ensure that it remains in perfect condition for generations of Seattle visitors to admire.

Throughout the first year of Concorde’s residence in the airpark, museum staff members worked to secure funding to build the Concorde HVAC system. The team used the unique HVAC system for the first presidential jet—which includes air conditioning and heating systems, a pressure boost system, and a digital control system that provides control and tracking of temperature and humidity levels, all incorporated into its forward cargo bay—as a reference. Unfortunately, this system couldn’t be precisely duplicated with Concorde because its baggage area is much smaller than that of Air Force One.

In November 2003, three British Airways engineers-—Ian Bishop, Kevin Moyes and David Pope—-flew in with G-BOAG from the United Kingdom. They, with British Airways engineer Don Dixon, who remained in London, helped the museum staff identify ways to utilize elements of Concorde’s onboard HVAC system, along with a new external system to achieve the stated goals of re-circulated air, stable temperature and humidity levels, energy efficiency and visitor comfort.

“All three were exceptional gentlemen, very knowledgeable and instrumental to the project,” recalled Evan Elliott, museum exhibit technician.

As the aircraft is on long-term loan, it was important to not alter it permanently.

“Kevin Moyes lifted a floor board to show how to bring the control and power wiring onboard,” recalls Fenton Kraft, museum engineering services manager.

He also suggested using the landing gear inspection ports to access the aircraft while preserving its integrity. Aircraft generally use a high pressure, auxiliary power unit, but this Concorde doesn’t have an APU turbine engine and the museum doesn’t have enough power flowing to the aircraft to run fans. The team needed to bring in an electrical unit to provide heating and cooling to the plane.

They decided to create a system with a recirculation mode to keep the hot and cold air within the plane. In the standard configuration, the air provided through the ground air connection is distributed though the cabin and is then exhausted. The hope of the museum’s crewmembers was that they could find a way to re-circulate the air in order to reduce the energy requirements while maintaining stable temperature and humidity levels. To remove the moist air and to control vapor pressure, they tapped into the ground air conditioning supply that runs through Concorde’s air distribution system above and below the floor-—including baggage compartments and the cockpit. They also removed pressure discharge valves that let air escape and modified the space to enable the air to leave and be pulled back in.

In July and August, the museum prepared Concorde for the air conditioning system installation. Elliott temporarily removed Concorde’s flooring to gain access to rear discharge valves that were to be used as a return air path for the external unit. Per British Airways’ recommendation, he also ran temperature and humidity sensor lines through Concorde’s right-rear landing gear inspection port window.

The museum ordered the custom system from Dan Mitchell of Applied Systems of Vancouver, Wash. In the spring of 2004, Mitchell met with facilities director Peter Bro, de Havilland Comet restoration crew chief Bob Hood, Fenton Kraft and senior curator Dennis Parks to develop a system. Based on the museum’s experience with desiccant dehumidifiers used on the Comet jetliner and Boeing 747 prototype in the past, Parks was comfortable with their use on Concorde.

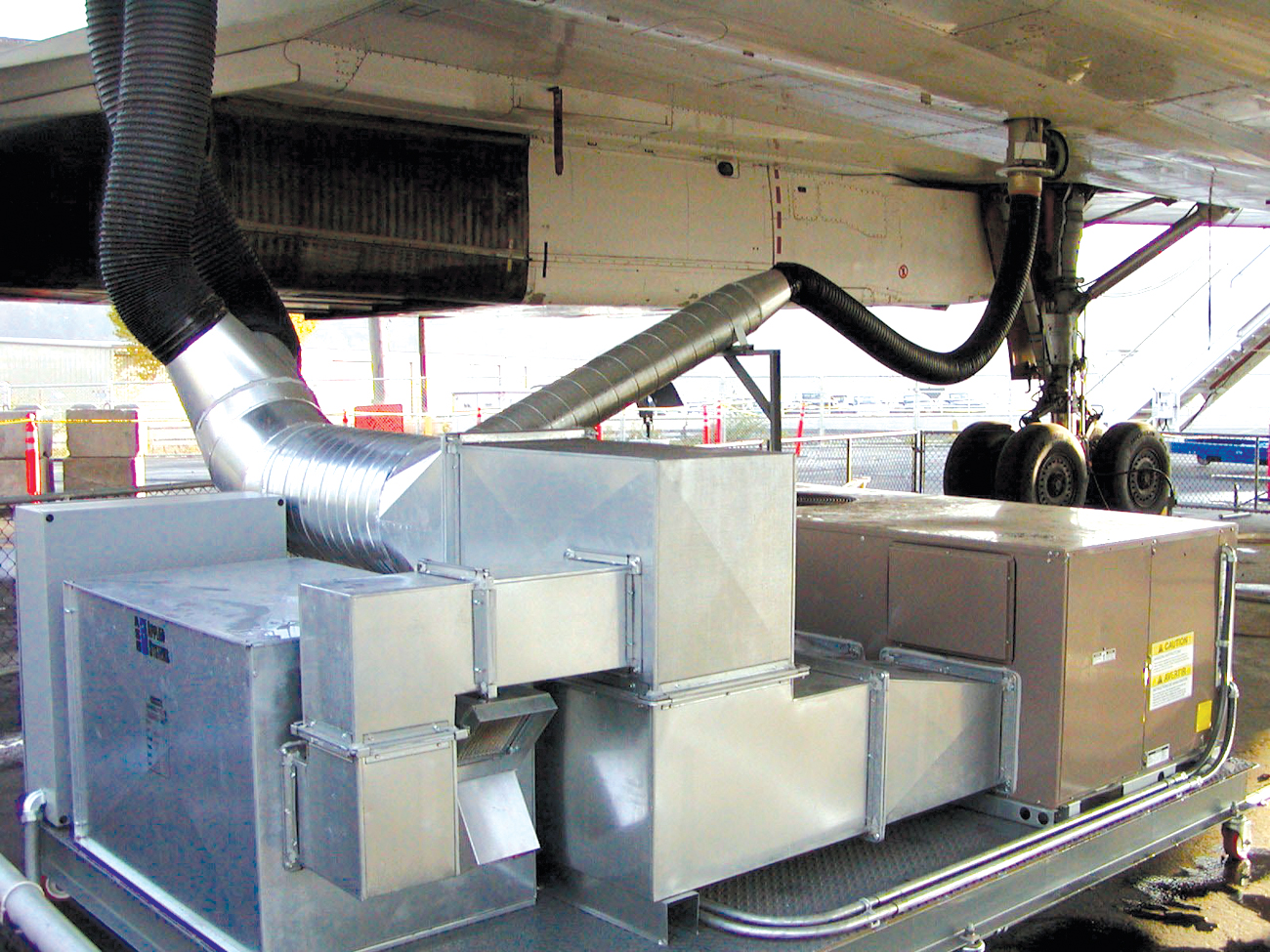

Mounted on the HVAC cart is an air handler that discharges into a pressure booster fan that supplies air to the plane. Heating and cooling is provided by a heat pump with supplemental heating for cold-weather conditions. A portion of the return air from the plane is run through the control system cabinet and the desiccant dehumidifier prior to mixing with the main air stream.

A SASCO electrical team from Woodinville, Wash., ran wiring to the plane and added a switch box for the 480-volt equipment. The McKinstry team from Seattle fabricated sheet metal pieces and foam seals to transition between Concorde and the unit, but didn’t alter or modify the aircraft. Installation began in September.

“It’s not every day contractors go from working on a 30-story high-rise HVAC system to that on a Concorde SST,” said Elliott, looking back on the project.

Kraft comments, “British Airways has been a huge help to us.”

The engineers provided a complete set of manuals. They have helped to identify ways to reconfigure and optimize the Concorde HVAC system to meet goals of artifact preservation and energy efficiency. The work can be removed as nothing was modified or cut. The original screws can be returned to bring the aircraft back to the condition it was in upon its arrival in Seattle. The unit is mounted on a wheeled cart so that it can move with the aircraft if and when Concorde ever needs to be repositioned.

In early October 2004, British Airways engineers Moyes and Bishop returned to see Concorde. They were pleased that the unit was running and that museum staff followed the approach they had recommended. On October 27, Dixon sent Elliott an e-mail saying, “You should be proud of your efforts…yours is the only museum which has gone for full air conditioning.”

The museum’s crew opened pressure relief ports to link return air ducts from the belly of Concorde to the ground unit.

This winter, Fenton Kraft and his staff are tracking data and adjusting the system to balance airflow between the various compartments on the plane to maintain optimal conditions for this unique aircraft and its equally valuable visitors.